ATI has developed the Superplate line of Flexplates to keep up with rampant HP gains made each year. Superplates are manufactured from a material with a 90,000 lb. tensile and 80,000 lb. yield strength to withstand thousands of cycles. Superplates are laser machined to avoid heat and stress that stamping inflicts on the part. The crank bolt holes and center hole are bored to exacting tolerances using ATI's in-house CNC machines. The Superplate uses the correct "grip length" crank bolts as dowels to prevent the plate from moving under high torque conditions. Why is a flexplate necessary? While manufacturing strives for precision, actually achieving it can be very difficult.

Therefore, believing that a crankshaft will be 100% in the center of the main line of the engine and thinking that everything will line up perfectly from the damper to the input shaft of the transmission is a fallacy. Because of the imperfect process, the flexplate needs to be flexible in order to make up for the "allowable" tolerances of the various part manufacturers. ATI's flexplate design is derived from a vast array of auto manufacturers, including big names like Lamborghini, Mercedes Benz, Bugatti, as well as 30 years of our own experience. A billet or thicker flexplate does not flex and therefore cannot absorb the "allowable tolerances" and that, in turn, can cause damage.

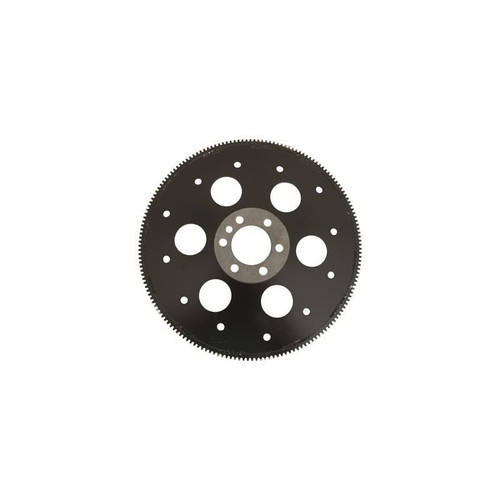

- Ring Gear Tooth Quantity:

- 168-tooth

- Rear Main Seal Style:

- 2-piece

- Engine Balance:

- Internal

- Flexplate Material:

- Steel

- Safety Rating:

- SFI 29.2

- Converter Bolt Pattern:

- 10.750 in./11.500 in.

- Crankshaft to Flywheel Attachment:

- 6-bolt

- Quantity:

- Sold individually.

- Notes:

- Flexplate has 1/2 in. size bolt holes.

- Make:

- Chevrolet

- Engine Family:

- Chevy big block Mark IV

- Engine Sizes:

- 6.5L/396-7.4L/454

- Years:

- 1963-1990

- Engine Family:

- Chevy small block Gen I

- Engine Sizes:

- 4.3L/262-6.6L/400

- Years:

- 1955-1986